Hydronic Radiant Floor Heating System: How to Choose It.

views: 11185 time: 2021-10-25

views: 11185 time: 2021-10-25

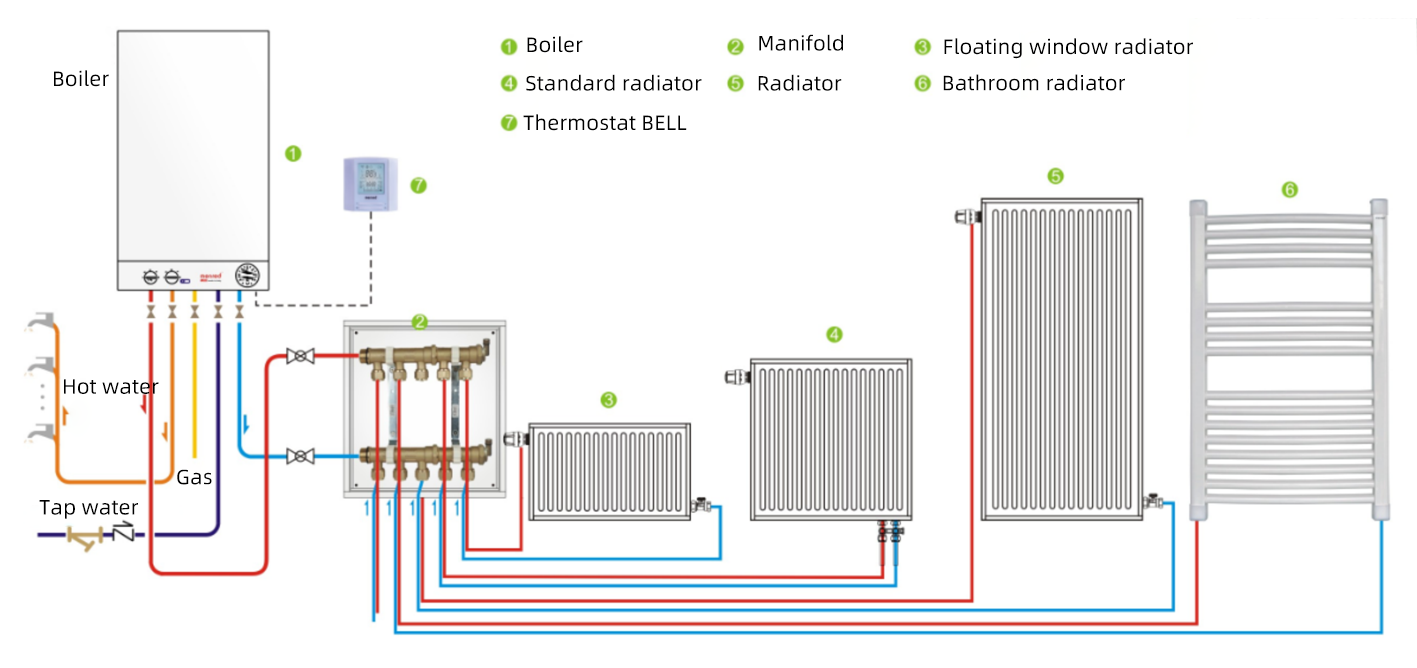

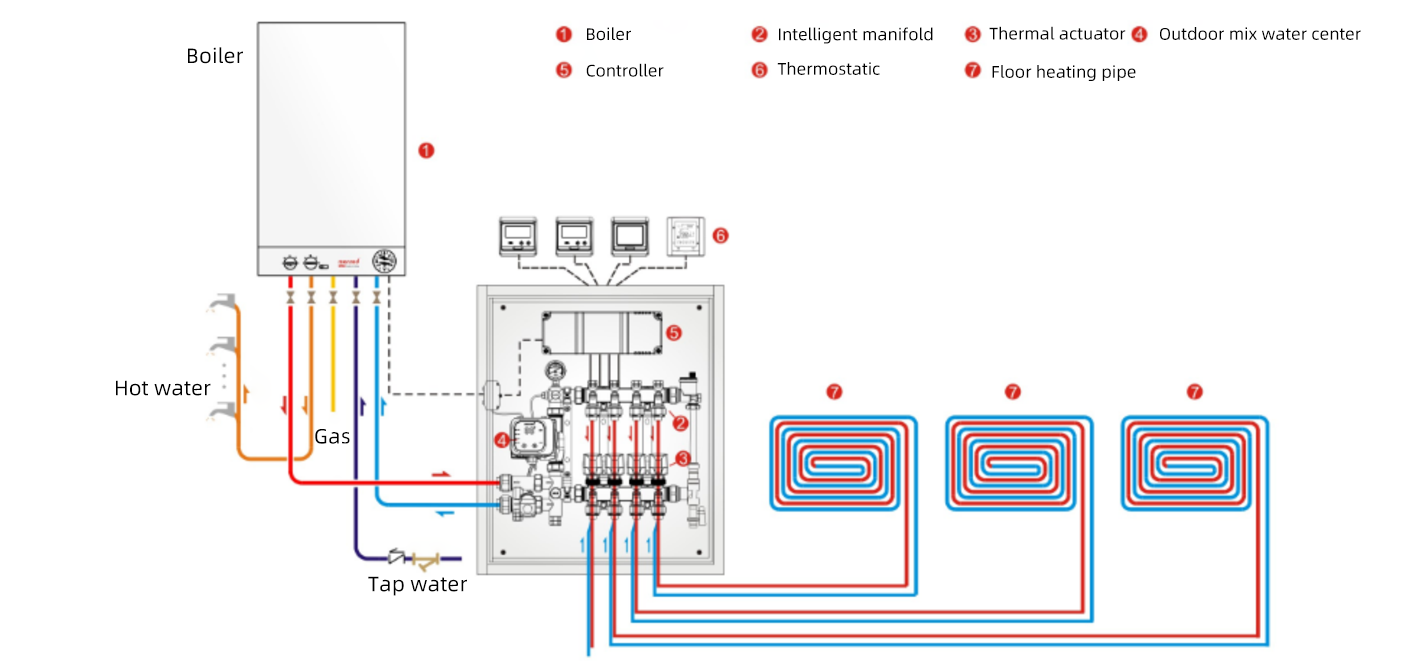

► Suitable for 60-120 square heating area.

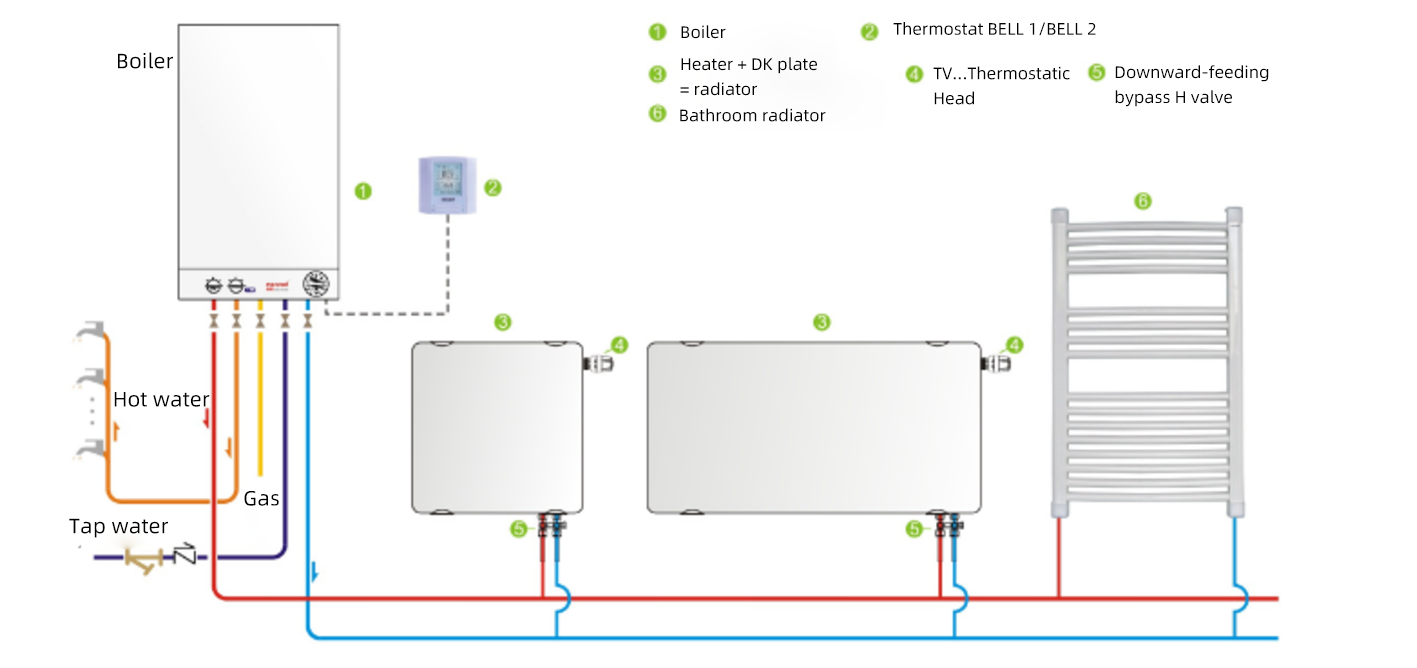

►Suitable for concealed pipe installation in newly renovated homes.One pipe to the end, no joint in the middle.

►Built-in thermostatic spool, add TV...thermostatic valve head, each room can be set to a different temperature.

►Installation is more safe and reliable, easy to use.

►Dual-use wall-mounted boiler, can provide domestic hot water at the same time.

►Suitable for open pipe installation in renovated homes and dark pipe installation in newly renovated homes.

►Built-in thermostatic spool, add TV...thermostatic valve head, each room can be set to a different temperature.

►Downward bypass H-valve, which is conducive to hydraulic balance.

►Suitable for 100-280 square feet heating area.

►Dual-use gas boiler, can provide domestic hot water at the same time.

►DK radiant panels can be added to provide a constant room temperature for a longer period of time.

►Suitable for 100-150 square heating area.

►Suitable for concealed pipe installation in newly renovated homes.

►Equipped with an indoor programmable thermostat for intelligent time control of room temperature.

►Differential pressure bypass: Differential pressure bypass is set for the manifold to ensure highefficiency of the pump and silent operation of the system.

►More safe and reliable for installation, and more convenient and comfortable to use.

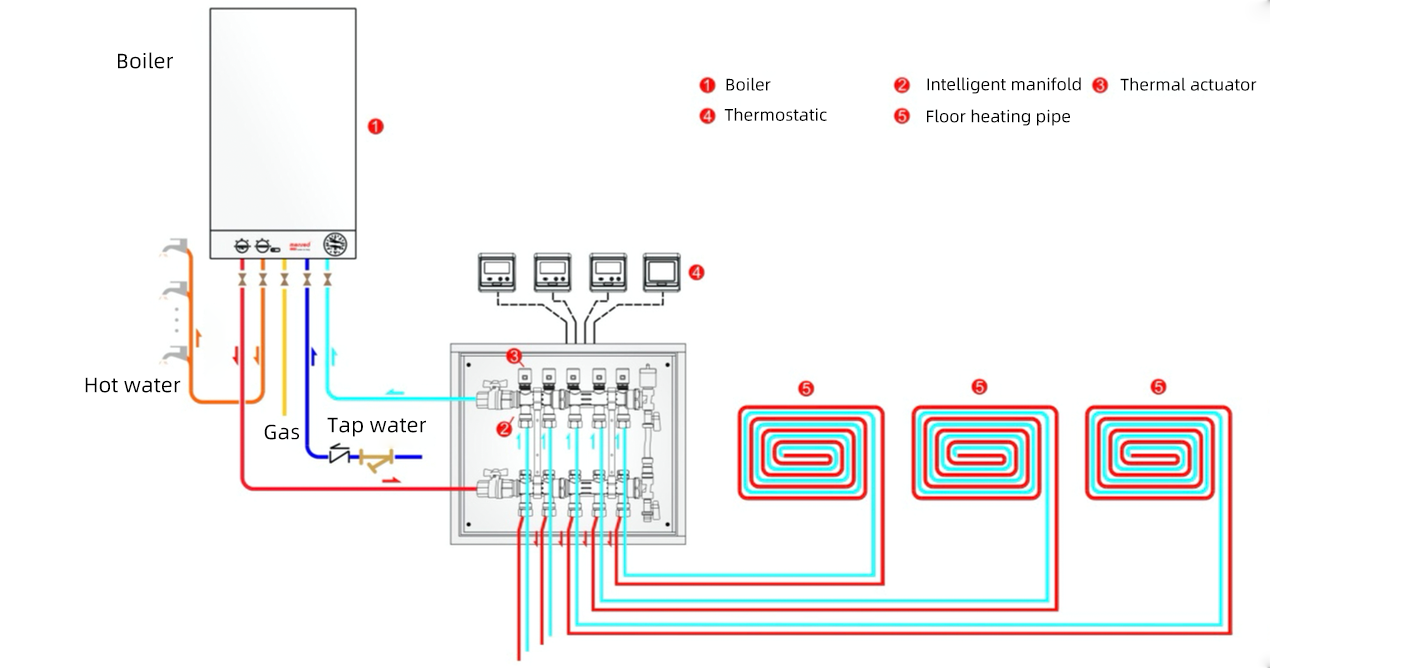

►Suitable for 100-300 square heating area.

►Suitable for concealed pipe installation for newly renovated families.

►Installation is more safe and reliable, convenient and comfortable to use.

►Equipped with central controller for underfloor heating, so that the wall-hung boiler, water pump and room temperature can be controlled linkage, more energy-saving.

►Equipped with indoor programmable thermostat, which can intelligently control room temperature in different time zones.

►Water mixing and energy saving center: constant system water supply temperature, precise heating, energy saving and comfortable.

►Dual-use wall-hung boilers, can provide domestic hot water also.

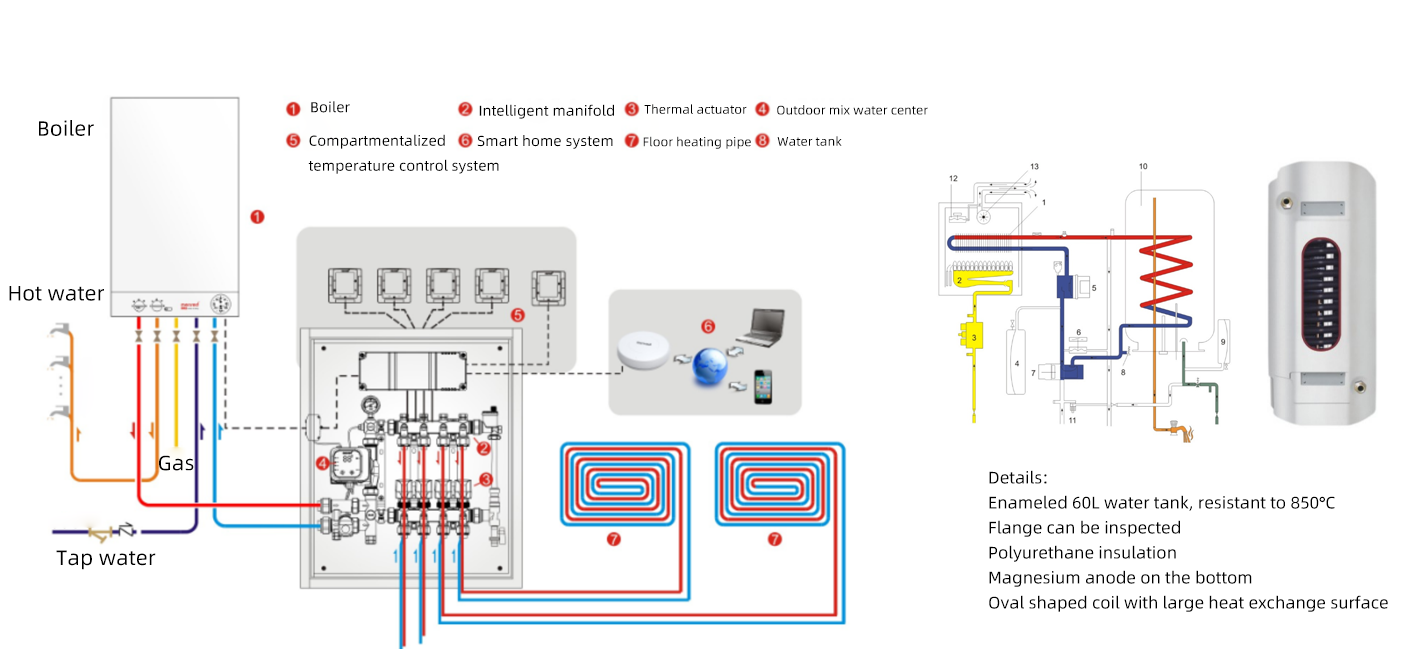

►Suitable for 100-300 square meters of heating area, suitable for concealed pipe installation in newly renovated homes.

►Wall-hung boiler + mixing water + floor heating: boiler side setting temperature 80 ℃, floor heating mixing water supply temperature is not higher than 50 ℃.

►Configure central controller for floor heating, so that wall-hung boilers, pumps, room temperature linkage control, more energy-saving.

►Partitioned temperature control: partitioned configuration of room temperature controller to meet different temperature needs Two-wire non-polarity, 12V safety voltage wiring.

►Water mixing and energy saving center: constant system water supply temperature, precise heating, energy saving and comfortable.

►RS485 communication interface: compatible with home intelligence system, remote control through computer or cell phone APP terminal.

►Volumetric dual-purpose wall-hung boiler with built-in 60-liter domestic hot water tank, constant domestic hot water temperature.

Point 1:The boiler should be allowed to fully circulate water at a temperature of about 75-85 °C, in order to achieve the standard combustion efficiency.

Some misconceptions about wall-hung boilers and floor heating:In order to meet the demand for floor heating water temperature, let the boiler function at a temperature below 60 °C, ignoring the wall-hung boiler's efficient operating conditions, the supply and outlet water temperature is too low. Therefore, wall-hung boilers are inefficient, resulting in high gas consumption, low heat conversion efficiency, and high exhaust temperature, resulting in high energy emissions.

Point 2:The return water temperature of the wall-hung stove must be above 50°C. If it is below 50°C, it results in condensation in the combustion chamber, which reduces the efficiency of heat transfer, wasting gas and reducing the service life of the wall-hung stove.

Note:the ideal water temperature difference between the inlet and outlet is 25 °C for wall-hung boilers, to ensure the best working condition of the wall-hung boilers. 85°C water temperature, while meeting the requirements of radiators, is not directly connected to the floor heating system.

To know more details, please contact us: sales@menred.com